Our mills in Thatta and Badin process locally grown Basmati and IRRI varieties using a combination of time-tested techniques and controlled mechanization. Each facility maintains separate compartments for paddy storage, husking, and polishing to ensure quality consistency.

Power Source: Onsite wind turbines supplement grid electricity during peak loads

Farmer Network: Contracts with 80-100 farms per milling season

Output: Capacity designed to handle typical local harvest volumes

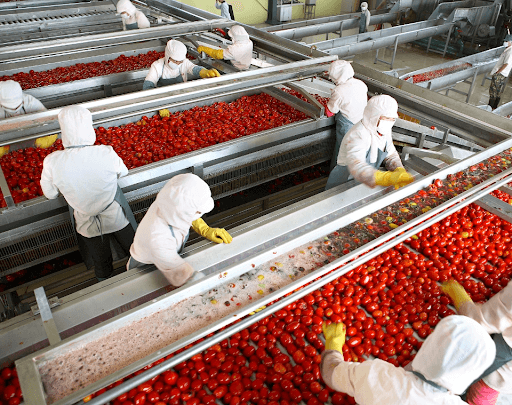

Small-batch processing allows us to adapt to seasonal tomato availability while maintaining hygiene standards. Our Hyderabad unit focuses on core product lines suited to local tastes and export requirements.

Energy: Solar panels power daytime operations; biogas backups for cooking

Scale: Designed for Sindh’s tomato production cycles (not arbitrary bottling counts)

Sourcing: Works directly with 3-4 cooperative farming groups

Using modified ghani presses alongside modern cold-press equipment, we extract oils from mustard, sesame, and other indigenous oilseeds while retaining traditional flavors.

Farmer-First Sourcing: Paying 20-30% above market for quality mustard, sesame, and sunflower seeds

Modern & Traditional Methods: German-engineered presses with nutrient-preserving techniques

Dual-Market Reach: Supplying both domestic kitchens and international health food markets

Own a stake in energy-independent processing units starting from PKR 500,000.

Copyright © 2025 Khas Agro Processing Limited. | Powered by Nooksofts.